Indigo Fermentation Kit (Small Kit) Liquid Volume: 15L / Container Capacity: 20L

- In stock, ready to ship

- Backordered, shipping soon

Small Kit (Liquid Volume: 15L / Container Capacity: 20L)

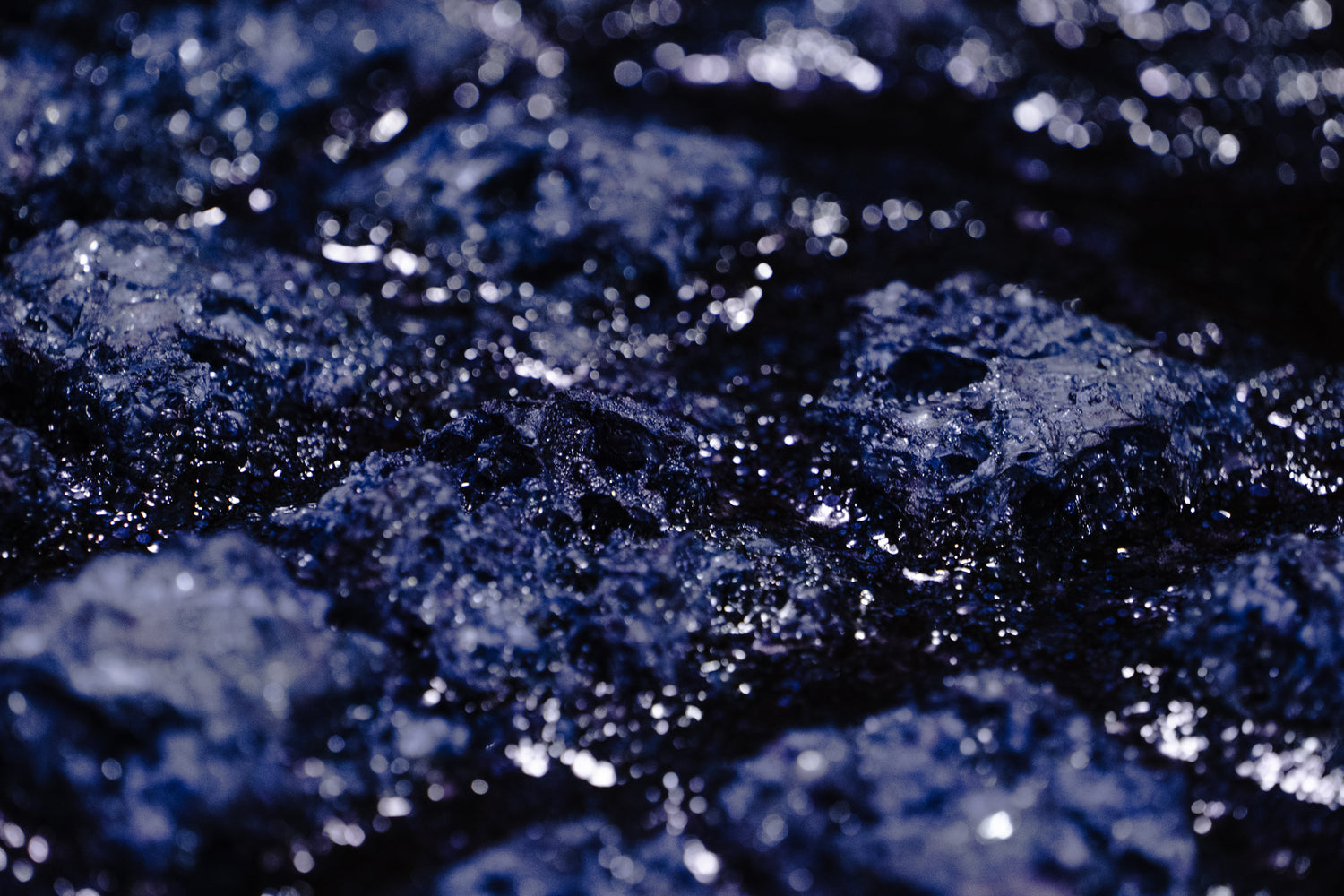

This kit is ideal for those who want to seriously begin indigo dyeing while managing and maintaining their natural lye fermentation vat (tennen aku hakkō-date).

In addition to dyeing, we encourage you to enjoy observing and recording the daily changes in the dye liquid — keeping notes on its condition and evolution as part of the experience!

The usable period of the dye depends on how well the fermented dye liquid is managed and how much dyeing is done.

For the Small Kit, the estimated usage period is 1 to 3 months, though at Watanabe’s, it has been successfully used for up to 6 months.

Please prepare the recommended container, as well as tools like a thermometer and pH meter for best results!

In this dyeing method, microbial fermentation reduces the indigo dye liquid, transforming the indigo pigment into a form that easily bonds with fabric, making dyeing possible.

However, the condition of the dye liquid changes daily.

Since the activity of the fermenting bacteria is sensitive to environmental factors such as temperature and pH, it is very important to observe and judge for yourself whether the dye is in a suitable state for use each day.

Download the Record Sheet Format Here

(Right-click on the displayed JPG file to save it.)

For example:

-

How much can I dye today?

-

When and what kind of maintenance is needed?

To help you make these daily decisions, we recommend using tools such as a thermometer and pH meter.

Storage Instructions After Purchase

Please use the kit as soon as possible after purchase.

For storage:

-

Fusuma (fermentation starter) should be kept in the refrigerator.

-

Sukumo (fermented indigo leaves), clam shell lime, and wood ash should be stored in a well-ventilated area, away from direct sunlight.

Moisture in the sukumo may hinder the fermentation process during indigo preparation.

Important Notes

-

If the amount of indigo dye liquid exceeds the recommended volume, the fermentation balance may be disrupted, resulting in weaker color or a shorter lifespan of the dye.

-

If the dye liquid is below the recommended amount, the dyeable area may become limited, making it difficult to dye anything but small items.

-

To maintain a stable fermentation environment, it’s important to keep the liquid at a consistent level.

-

The usable period may vary depending on the condition of the fermentation bacteria and how frequently you dye.

For the first two to three washes after purchase, we recommend gently hand washing in warm water (around 40°C / 104°F) with an appropriate amount of neutral detergent.

Our genuine indigo-dyed products undergo thorough decolorizing and natural color-setting treatments after dyeing; however, vigorous rubbing during use may cause some color transfer.

During washing, you may notice a brownish-yellow tint—this is due to natural alkaline residues from the dyeing process. Repeated washing will remove these residues, revealing the vibrant, unique indigo blue.

Each product is handmade, so color and pattern variations are normal and contribute to the uniqueness of the item.

The alkaline residues can react with sunlight and other ultraviolet rays, potentially causing discoloration. Please store your product away from direct sunlight.