CHARLIE II SHOULDER BAG (M)

- In stock, ready to ship

- Backordered, shipping soon

Product Specification

14oz original denim pants Distressed, natural dyeing Regular fit, straight silhouette High rise Button fly Red selvedge Zip detail inside right back pocket Original zipper slider, copper neoba buttons, rivets Natural dyeing deerskin patch

100% cotton

The color and pattern of the fabric used may differ slightly from the image. Please note that the product may shrink slightly after washing.

Products that have been naturally dyed will have different textures. Also, some products may have dirt or other stains. They may shrink slightly after washing. Please be aware of this in advance.

Details

CHARLIE II SHOULDER BAG (M)

COLOR: BLACK, GREEN, OLIVE

SIZE: ONE SIZE

A Military Shoulder Bag made from a woven nylon twill fabric.

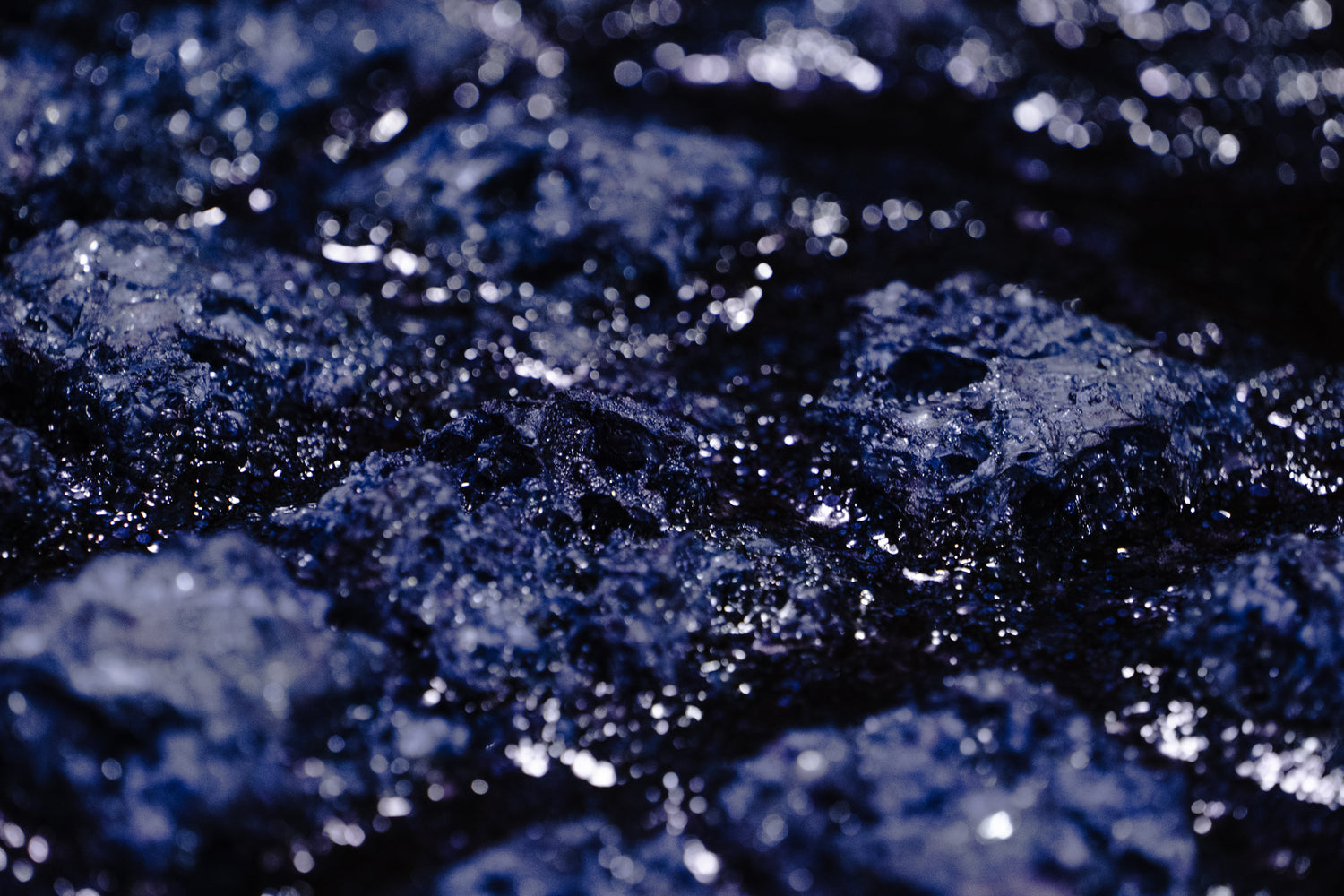

Damaged Finish

Natural Dyes

SWISS riri fastener

Custom zip fastener closure

100% nylon

|

SIZE |

HEIGHT |

WIDTH |

GUSSET |

|

ONE SIZE |

twenty four |

36 |

15 |

UNIT : cm

Items that are finished with Natural Dye will experience different textural finishes where no two are Also, there may be pieces that have mud left on the finished garment as a result of the treatment. Please be aware that there may also be slight variations in color or pattern from the images shown due to the nature of the fabric being used. Additionally the style will experience some shrinkage when washed.

洗濯の際に使用する洗剤は中性洗剤を使用し、蛍光増白剤や漂白剤の入っていないものをご使用ください。

購入後最初の2、3回の洗濯は中性洗剤を適量いれたお湯( 40度程度 )で、優しく手洗いすることをおすすめいたします。

本藍染製品は、染色後に可能な限りアク抜きと天然色止め加工を施しておりますが、使用時の激しいこすれなどにより、色移りする可能性があります。

洗濯時に茶黄色の色素が出る場合がありますが、これは藍染特有のアク成分で、洗濯を繰り返すうちにアクが抜け、天然藍染特有の鮮やかな色味が増していきます。

製品は全て手作りのため、色や柄の出方等がそれぞれ異なります。

日光などの紫外線にアクが反応し変色する可能性がありますので、紫外線を避けて保管してください。

--------

CARE INSTRUCTIONS

Upon arrival, the product is ready to be used. All products are hand-dyed, making each one unique in color and pattern.

When washed, a yellowish-brown pigment may appear on the product, a reaction caused by the natural lye used in our indigo dye baths. This pigment will fade after several washes.

The product has already gone through many rounds of lye removal and treatment to ensure the color is of the highest quality. However, with usage over time the color still may fade.

To prevent discoloration, for the second or third wash we recommend handwashing it gently in lukewarm water with a small amount of laundry detergent. Please refrain from using whitening or bleaching agents.

Please avoid leaving the product in direct sunlight as UV rays may trigger a reaction with the lye in the product and cause discoloration.