Agriculture

October 15, 2024

At Watanabe’s our indigo making process begins with organic compost-based soil preparation.

We avoid herbicides and pesticides, instead focusing on nurturing healthy, fertile soil. This approach enriches the ecosystem of our fields, naturally suppressing pests and diseases.

Our indigo, cultivated through the blessings of nature, the land, and the bonds of our local community, develops a deep, vibrant blue. Harvested at peak summer, the leaves and stems are carefully sorted in a process called Aikonashi, then sun-dried to perfection

We avoid herbicides and pesticides, instead focusing on nurturing healthy, fertile soil. This approach enriches the ecosystem of our fields, naturally suppressing pests and diseases.

Our indigo, cultivated through the blessings of nature, the land, and the bonds of our local community, develops a deep, vibrant blue. Harvested at peak summer, the leaves and stems are carefully sorted in a process called Aikonashi, then sun-dried to perfection

read

Fermented Indigo (Sukumo)

2024.10.15

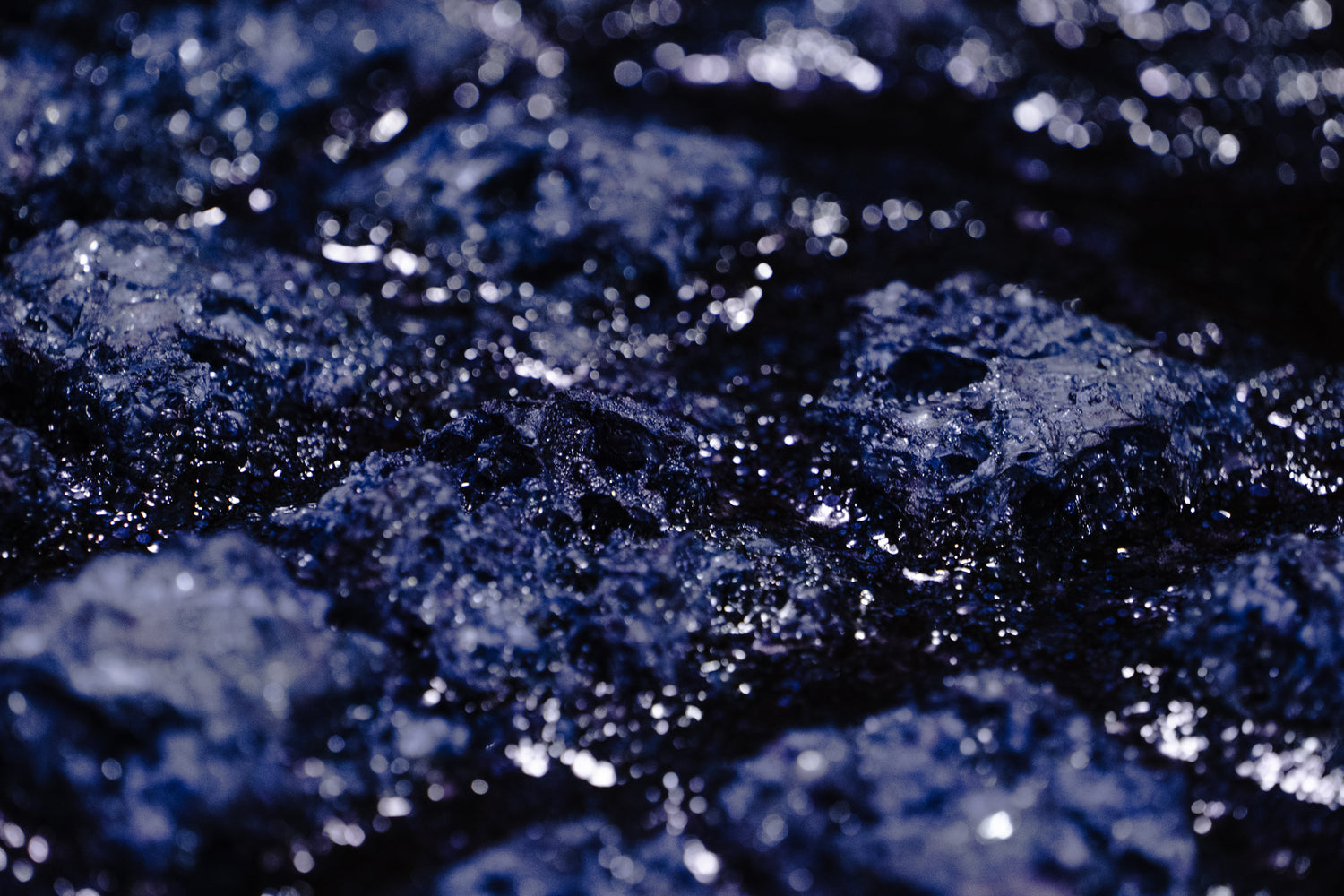

Sukumo, the traditional Japanese fermented indigo dye, is created by spreading dried indigo leaves on a fermentation bed (nebedoko). After moistening and mixing the leaves, the fermentation process begins.

Over 100 days, the indigo undergoes an initial resting phase (nesekomi) followed by more than twelve rounds of turning (kirikaeshi). During these stages, the leaves gradually transform into rich, vibrant sukumo. At peak fermentation, the core temperature reaches 70°C (158°F), producing steam and a strong, ammonia-like aroma.

While the fermentation bed may appear motionless, it teems with invisible microbial activity, requiring keen sensory observation throughout the process.

Over 100 days, the indigo undergoes an initial resting phase (nesekomi) followed by more than twelve rounds of turning (kirikaeshi). During these stages, the leaves gradually transform into rich, vibrant sukumo. At peak fermentation, the core temperature reaches 70°C (158°F), producing steam and a strong, ammonia-like aroma.

While the fermentation bed may appear motionless, it teems with invisible microbial activity, requiring keen sensory observation throughout the process.

read

Dyeing

October 15, 2024

At Watanabe’s, we craft our indigo dye using sukumo (fermented indigo), wood ash, shell lime powder, and wheat bran—all natural materials.

Over two weeks, we nurture fermentation to gradually intensify the dye’s potency through a traditional Japanese method called Sukumo Aidate.

Within the dye vat, a microbial ecosystem thrives, reminiscent of a living galaxy where societies form, villages emerge, and life pulses unseen. This invisible vitality imbues our indigo with its deep, soulful blue.

Over two weeks, we nurture fermentation to gradually intensify the dye’s potency through a traditional Japanese method called Sukumo Aidate.

Within the dye vat, a microbial ecosystem thrives, reminiscent of a living galaxy where societies form, villages emerge, and life pulses unseen. This invisible vitality imbues our indigo with its deep, soulful blue.

read